Digital Manufacturing and Materials Characterization Laboratory (DMMC Lab)

The newly equipped Digital Manufacturing and Materials Characterization Laboratory (DMMC Lab) is available for students to use under the guidance of technically competent personnel.

The Laboratory is also used for external collaborations with industry partners, funded research projects and other academic activities. Lab’s equipment is summarized as follows:

Additive Manufacturing Technologies

- 3D Printer Fused Filament Fabrication (FFF) technology with 50μm precision, with independent dual extrusion capabilities

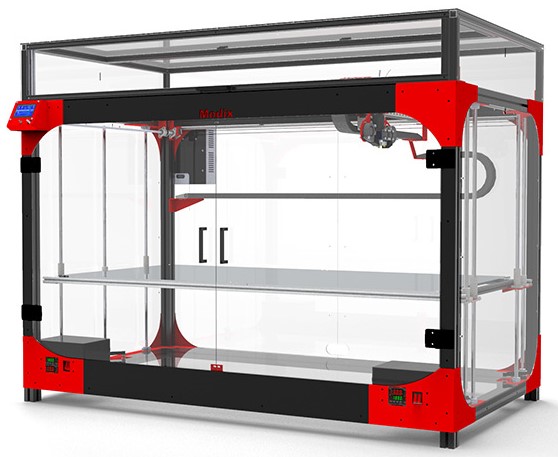

- Large Scale 3D Printer Fused Filament Fabrication (FFF) technology with maximum build plate 1200 x 600 x 600 mm

- 3D Printer Composite Filament Fabrication (CFF) technology with 100μm precision, with reinforcement of Continuous Carbon Fiber, Fiber Glass and Kevlar.

- 3D Printer Liquid-Crystal Display (LCD) technology with 10μm precision, compatible with 3rd party resins and instant curing in each layer

- 3D Printer Stereolithography (SLA) technology with 25μm precision, with a variety of different resins such as Castable, Flexi etc.

- 3D Printer Selective Layer Sintering (SLS) technology with 100μm precision and post processing equipment (automated sieve and sandblasting apparatus)

- 3D Printer Direct Ink Writing (DIW) technology with capabilities of printing custom materials such as ceramics, clays and hydrogels, with maximum availability of four different extruder heads.

Subtractive Manufacturing Technologies

- 4-axis Computer Numerical Control (CNC) ideal for wood, plastic, and acrylic materials with Coordinate Measurement Machine (CMM) sensor attached to it

- 40-Watt Laser Cutter CO2 for cutting and engraving a variety of materials (wood, plastic, carton, cork, acrylic etc.)

3D Scanning Technologies

- Portable White Light technology 3D Scanner with 500microns precision, 16fps and texture scanning capabilities

- Desktop Laser technology 3D Scanner with 100microns precision, texture scanning capabilities and automated turntable for a 360o scanning

- Portable Kinect Sensor with texture scanning capabilities

- Unmanned Aerial Vehicle (UAV) with Photogrammetry technology capabilities

Advanced Materials Testing

- Tensile testing machine equipped with load cells 500N and 50kN, capable of performing tensile, compression, bending tests, shear puncture, cyclic as well as Brinell Hardness tests.

- Data acquisition apparatus with strain gauges and Linear Variable Differential Transducers (LVDT) attached to Tensile testing machine

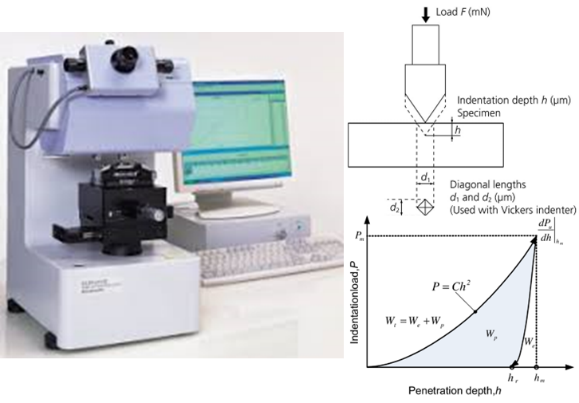

- Dynamic Ultra Micro Hardness Tester, equipped with Berkovich indenter and micro-compression capabilities with 10nm and 100nm flat-section indenters.

Microscopy Analysis

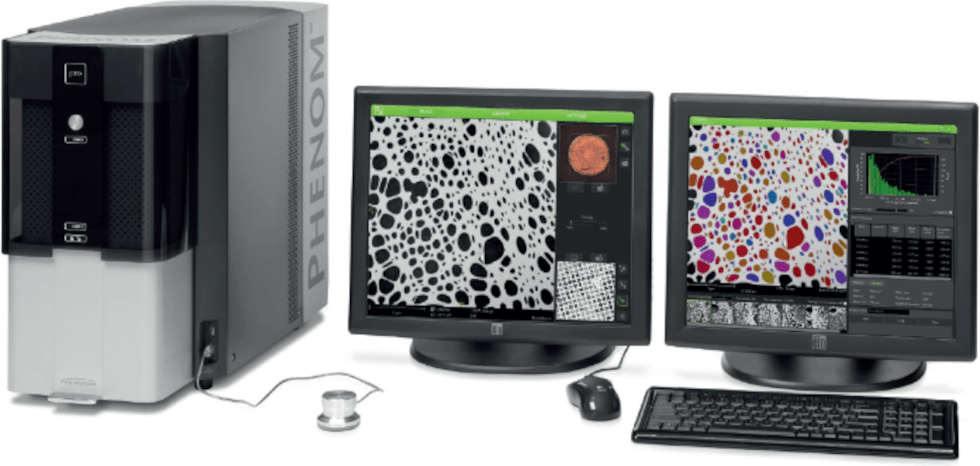

- Desktop Scanning Electron Microscope (SEM) with magnification range 160x-150.000x and resolution ≤8nm, with several analysis software

- Energy-Dispersive X-Ray (EDX) Analysis

- Elemental Mapping Analysis

- Particle Analysis

- Poro-Metric Analysis

- Fiber-Metric Analysis

- 3D Roughness Reconstruction

- Digital optical microscope with magnification range 20x-200x

- Stereomicroscope of 225x magnification and digital camera attached to it

Supplementary Equipment

- Ultrasonic Sonicator for nanomaterials dispersion

- Infrared Thermo-Camera with object Temperature Range -40oC – +650oC

- Air-circulated drying and heating oven up to 380oC

- Desktop automated microtome up to 30x40mm workpiece and accuracy of ±0.01mm

- Grinding and Polishing machine with self-cooling system

- Mini Sputter Coater with Au, Au/PD and Carbon coating capabilities, fitted with glow-discharged function

- Desktop Extruder with Spooler, suitable for production of experimental FDM filaments

Advanced Software

- Computer Aided Design (CAD) – Solidworks, Rhinoceros

- Finite Element Analysis (FEA) – ANSYS

- Computer Aided Manufacturing (CAM) – SolidCAM

- Point Cloud and Mesh Manipulation – Geomagic, Spaceclaim

- 3D Scanning Software – Artec Studio, Scan Studio

- Implicit Modeling Engine – NTopology